How Pressure Compensating Valves Enhance Performance in Hydraulic Systems

Date: 2026-01-10 Categories: Industry News Hits: 4493

1. Introduction to Pressure Compensating Valves

In the realm of hydraulic systems, efficiency and reliability are paramount. **Pressure compensating valves** play a crucial role in optimizing these systems, ensuring consistent performance under varying load conditions. These valves are engineered to maintain a preset pressure, thereby enhancing the overall functionality of hydraulic systems in various industrial applications.

2. What Are Pressure Compensating Valves?

Pressure compensating valves are specialized components designed to regulate fluid flow in hydraulic systems. Unlike standard valves, which may fail to adapt under fluctuating pressures, pressure compensating valves automatically adjust to maintain a consistent pressure level. This ensures that hydraulic actuators operate smoothly, regardless of the load, thereby improving efficiency and reducing wear on system components.

The Basics of Hydraulic Systems

To fully appreciate the significance of pressure compensating valves, it's essential to understand the fundamentals of hydraulic systems. Hydraulic systems operate using pressurized fluid to transmit power. They consist of several components, including pumps, actuators, and valves, which work together to perform various tasks, from lifting heavy loads to controlling machinery.

3. How Pressure Compensating Valves Work

Pressure compensating valves function by utilizing a feedback mechanism that adjusts the flow based on the pressure exerted by the load. When the load increases, the valve responds by adjusting the flow rate to maintain a constant pressure, effectively preventing pressure spikes that could damage the system.

The Mechanism of Action

The core of a pressure compensating valve is its **spring-loaded diaphragm** or piston. When fluid enters the valve, it exerts pressure on the diaphragm. As the load increases, the valve opens to allow more fluid to flow, maintaining equilibrium in the system. This not only prevents pressure fluctuations but also enhances the **response time** of the hydraulic system, making operations smoother and more efficient.

4. Benefits of Pressure Compensating Valves in Hydraulic Systems

Implementing pressure compensating valves in hydraulic systems offers a multitude of benefits:

Improved Operational Efficienc

By ensuring a consistent pressure level, these valves enhance the efficiency of hydraulic systems. This means less energy is wasted, leading to lower operational costs.

Reduced Wear and Tear

Pressure spikes can cause severe damage to hydraulic components. By mitigating these spikes, pressure compensating valves prolong the lifespan of pumps, actuators, and other critical components.

Enhanced System Stability

Stable pressure levels lead to improved system performance. This stability translates into better control over hydraulic operations, allowing for precise movements and reactions.

Increased Safety

Consistent pressure regulation reduces the risk of accidents caused by pressure failures or surges, contributing to a safer working environment.

5. Applications of Pressure Compensating Valves

Pressure compensating valves find extensive use across various industries, including:

Construction Machinery

In construction equipment, these valves are critical for controlling hydraulic lifts and excavators, ensuring that heavy loads are managed safely and efficiently.

Agricultural Equipment

In agricultural machinery, such as tractors and harvesters, pressure compensating valves help optimize performance, making farming operations more efficient and cost-effective.

Manufacturing and Automation

In automated production lines, these valves play a pivotal role in controlling robotic arms and conveyors, enhancing precision and reliability in manufacturing processes.

Marine and Aerospace Applications

In the marine and aerospace industries, pressure compensating valves are employed to ensure the reliability and safety of hydraulic systems in various applications, from lift systems to steering controls.

6. Choosing the Right Pressure Compensating Valve

Selecting the appropriate pressure compensating valve for specific applications requires careful consideration of several factors:

Flow Rate and Pressure Specifications

Understanding the required flow rate and operating pressure is crucial. Valves must be matched to the system's specifications to function effectively.

Material Compatibility

Considering the fluid used in the hydraulic system is essential for valve longevity. Materials must be compatible with the hydraulic fluid to avoid corrosion and degradation.

Size and Configuration

The physical size and configuration of the valve must align with the hydraulic system design. Proper fitting ensures optimal performance and ease of maintenance.

7. Maintenance and Reliability of Pressure Compensating Valves

To ensure the reliability of pressure compensating valves, regular maintenance is essential. This includes:

Routine Inspections

Regular inspections help identify potential issues before they escalate. Checking for leaks, wear, and proper functioning is crucial for maintaining system integrity.

Fluid Quality Management

Maintaining the quality of hydraulic fluid is vital. Contaminated fluid can damage valves and other components, leading to system failures.

Timely Replacements

Replacing worn or damaged valves promptly prevents system inefficiencies and potential hazards, ensuring smooth operations.

8. Future Trends in Pressure Compensating Valve Technology

The evolution of pressure compensating valves continues, with several trends shaping the future of this technology:

Smart Technology Integration

The integration of smart technology, such as IoT sensors, allows for real-time monitoring and adjustments, enhancing the performance and efficiency of hydraulic systems.

Increased Customization

Manufacturers are focusing on providing customizable valve solutions tailored to specific industry needs, ensuring optimal performance across diverse applications.

Sustainability Initiatives

As industries move towards sustainability, pressure compensating valves are being designed with eco-friendly materials and energy-efficient features, reducing their environmental footprint.

9. FAQs

What is a pressure compensating valve?

A pressure compensating valve is a device that maintains a constant pressure in hydraulic systems, adjusting the flow rate as needed to accommodate varying load conditions.

How do pressure compensating valves differ from standard valves?

Unlike standard valves, which may not adapt to pressure changes, pressure compensating valves automatically adjust to maintain consistent pressure levels, enhancing system performance.

What are the benefits of using pressure compensating valves?

Benefits include improved operational efficiency, reduced wear and tear on system components, enhanced stability, and increased safety in hydraulic operations.

In which industries are pressure compensating valves commonly used?

They are widely used in construction, agriculture, manufacturing, marine, and aerospace industries, among others.

How can I ensure the reliability of my pressure compensating valves?

Regular inspections, maintaining fluid quality, and timely replacements are crucial for ensuring the reliability and efficiency of pressure compensating valves.

10. Conclusion

Pressure compensating valves are essential components in enhancing the performance of hydraulic systems. By maintaining consistent pressure levels, they contribute to improved efficiency, reduced wear, and increased safety across various applications. As technology continues to evolve, these valves will play an integral role in optimizing hydraulic systems, paving the way for more advanced and sustainable solutions. Understanding their functionality, benefits, and applications is crucial for industries looking to enhance their hydraulic operations.

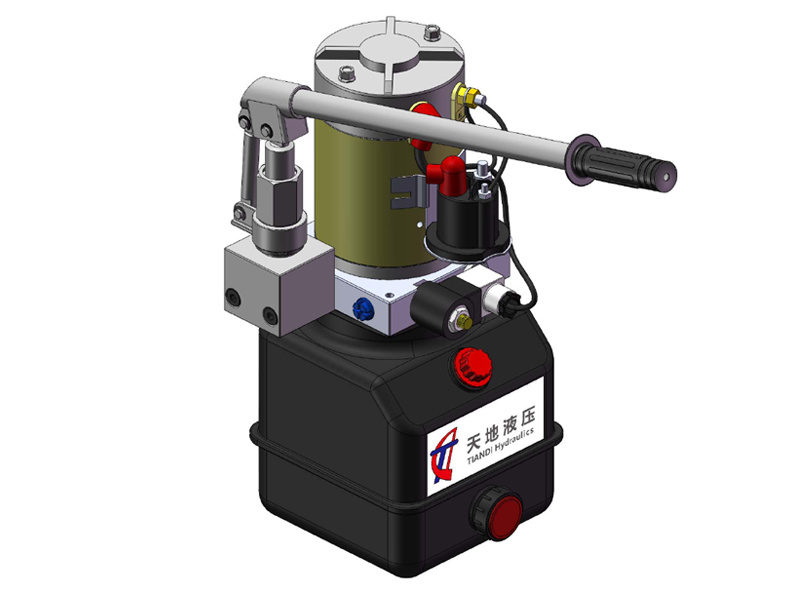

DC power unit & hand pump

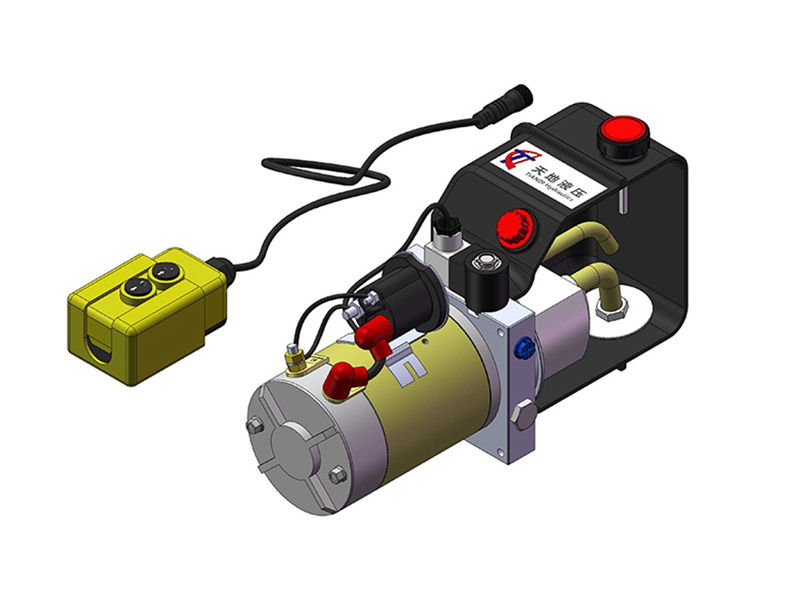

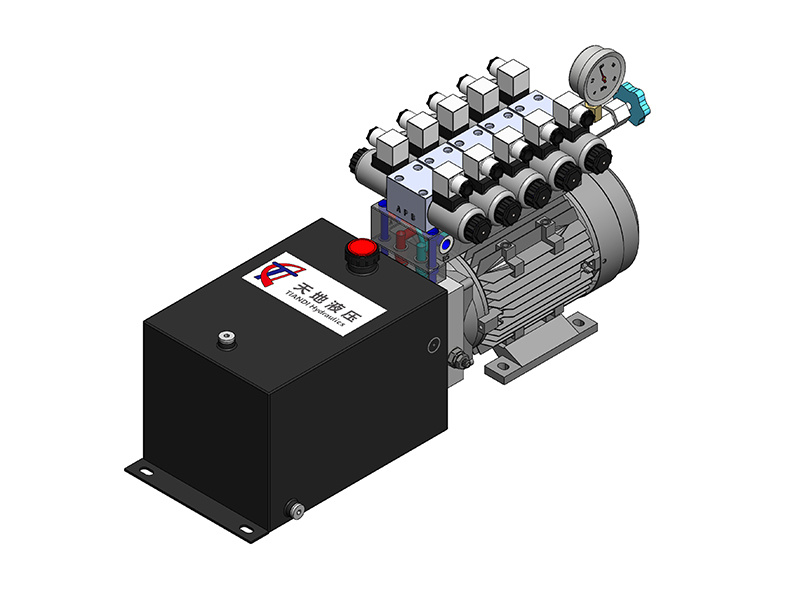

DC power unit & hand pump  DC power unit

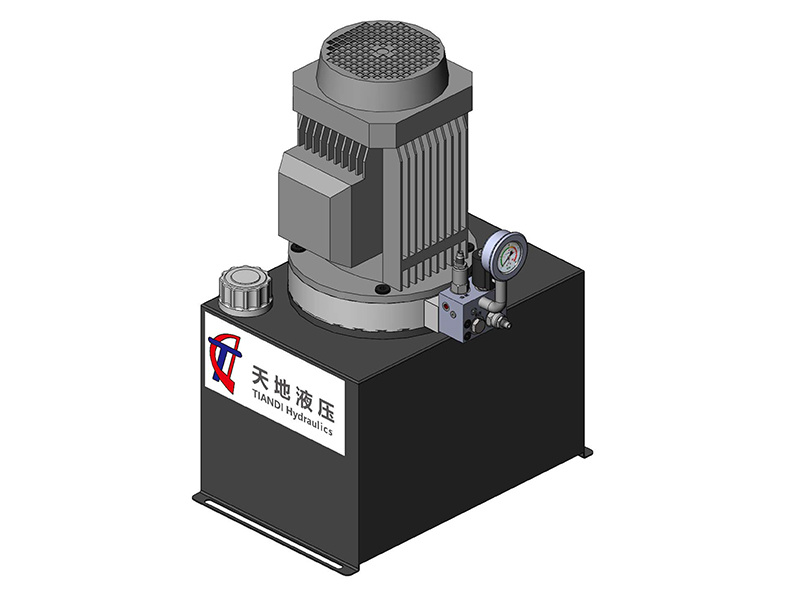

DC power unit  AC hydraulic station

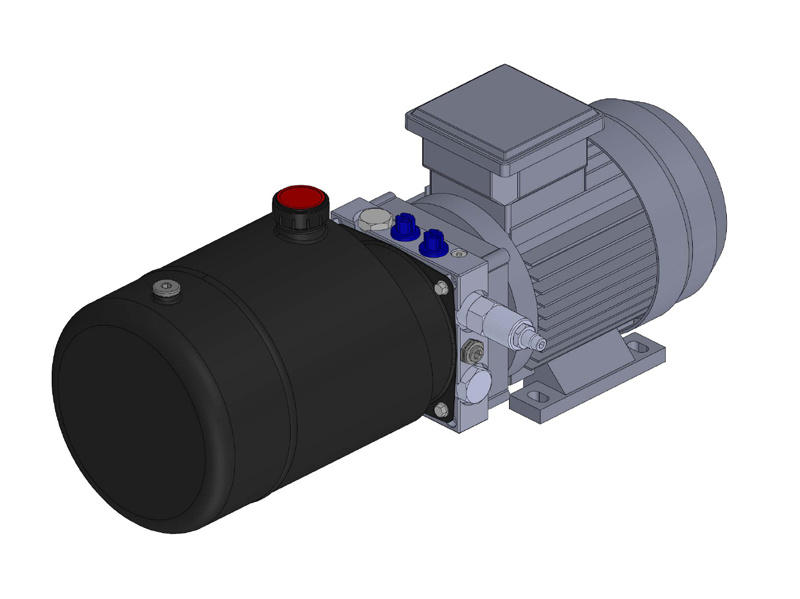

AC hydraulic station  Platform power unit

Platform power unit  AC power unit

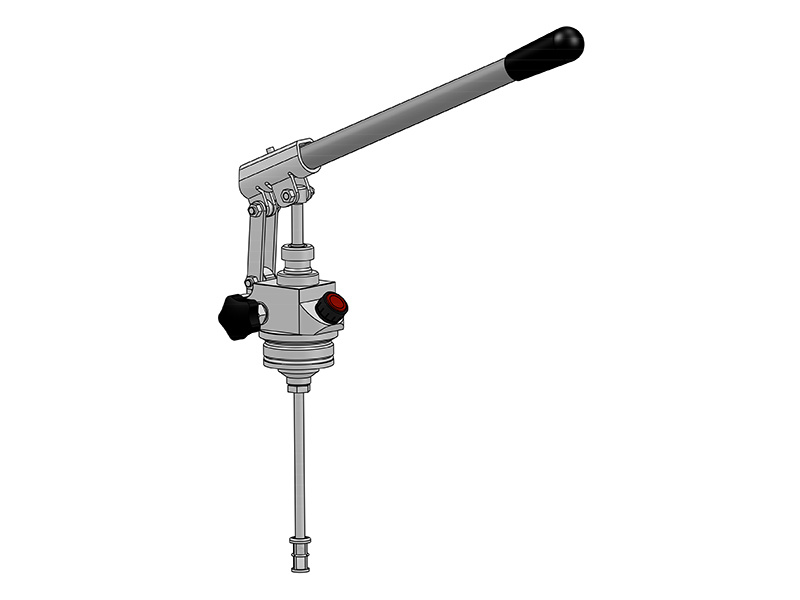

AC power unit  25CC/45CC double action hand p...

25CC/45CC double action hand p...  25CC/45CC single action hand p...

25CC/45CC single action hand p...  25CC double-plunger hand pump

25CC double-plunger hand pump  20CC single action hand pump

20CC single action hand pump  6CC single action hand pump

6CC single action hand pump  Hydraulic system circuit block

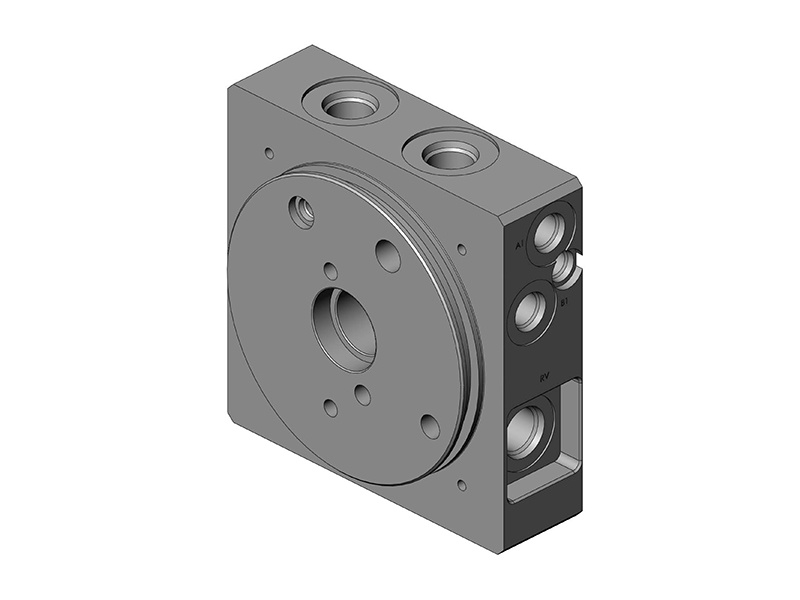

Hydraulic system circuit block  Power unit center block

Power unit center block  Cartridge valve

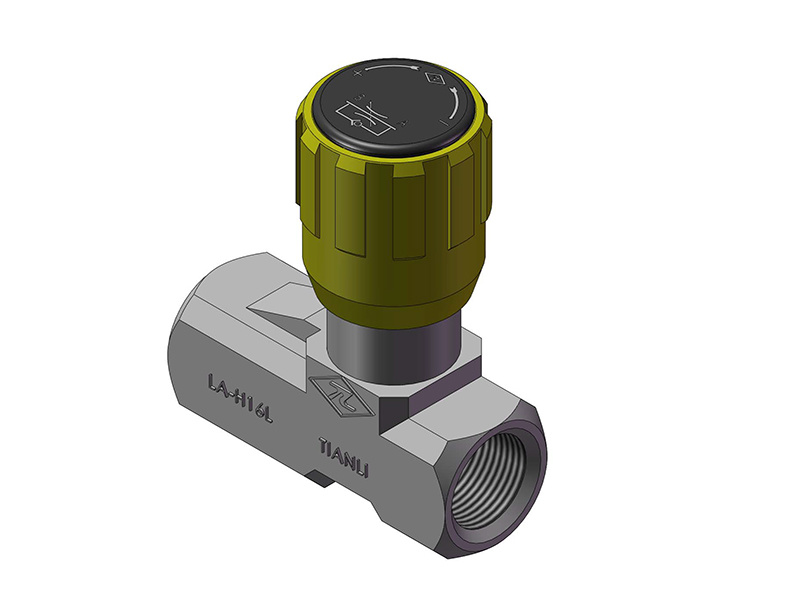

Cartridge valve  Flow control valve

Flow control valve  Solenoid directional valve

Solenoid directional valve  DC motor

DC motor  Gear pump

Gear pump