How Threaded Cartridge Valves are Revolutionizing Manufacturing Processes

Date: 2026-01-10 Categories: Industry News Hits: 165

Introduction to Threaded Cartridge Valves in Manufacturing

In the industrial landscape, **valves** play a critical role in controlling the flow of fluids and gases in various manufacturing processes. Among the different types of valves, **threaded cartridge valves** are gaining immense popularity due to their remarkable efficiency and versatility. This article explores how these innovative components are revolutionizing manufacturing processes, enhancing productivity, and driving cost savings.

Understanding Threaded Cartridge Valves

Threaded cartridge valves are compact, modular components designed to regulate fluid flow in a variety of applications. Unlike traditional valves, which often require extensive modifications for installation, threaded cartridge valves can be easily integrated into existing systems. Their design features a threaded body that allows for secure connections, making them ideal for both new installations and retrofitting existing equipment.

Key Features of Threaded Cartridge Valves

1. **Modular Design**: The modular nature of threaded cartridge valves allows for easy installation and replacement, minimizing downtime during maintenance.

2. **Compact Size**: Their small footprint makes them suitable for tight spaces, enhancing flexibility in system design.

3. **High Flow Capacity**: Despite their size, threaded cartridge valves can handle substantial flow rates, making them suitable for a wide range of applications.

4. **Durability**: Constructed from high-quality materials, these valves are designed to withstand harsh operating conditions, ensuring longevity and reliability.

The Advantages of Using Threaded Cartridge Valves

The adoption of threaded cartridge valves in manufacturing processes offers several advantages that contribute to enhanced operational efficiency and cost savings.

1. Improved Efficiency and Performance

Threaded cartridge valves provide precise control over fluid flow, which is essential for optimizing manufacturing processes. Their ability to maintain consistent flow rates leads to improved performance, reducing waste and ensuring that systems operate at maximum efficiency.

2. Cost-Effectiveness

By minimizing the need for extensive piping modifications and reducing installation time, threaded cartridge valves help lower overall project costs. Their durability also means fewer replacements and repairs, resulting in significant savings over time.

3. Enhanced System Flexibility

The modular design of threaded cartridge valves allows manufacturers to easily adapt their systems to changing needs. Whether it’s scaling up production or modifying processes, these valves can be quickly installed or removed without disrupting the entire system.

Applications of Threaded Cartridge Valves in Manufacturing

Threaded cartridge valves are widely used across various manufacturing sectors due to their versatility. Here are some notable applications:

1. Hydraulic Systems

In hydraulic systems, threaded cartridge valves control the flow and pressure of hydraulic fluids. Their precise control mechanisms enhance the performance of hydraulic machinery, making them essential in industries such as automotive and aerospace.

2. Pneumatic Systems

Pneumatic systems benefit from threaded cartridge valves as they can regulate compressed air flow. This is crucial in manufacturing processes that rely on air power for automation and control.

3. Chemical Processing

Threaded cartridge valves are also used in chemical processing plants, where they control the flow of corrosive and hazardous fluids. Their robust construction ensures safety and reliability in potentially dangerous environments.

4. Food and Beverage Industry

In the food and beverage industry, hygiene and safety are paramount. Threaded cartridge valves, made from non-corrosive materials, are ideal for controlling process fluids without contaminating products.

Future Trends in Threaded Cartridge Valve Technology

As manufacturing processes continue to evolve, so too does the technology behind threaded cartridge valves. Some future trends include:

1. Smart Valve Technology

The integration of smart technology into threaded cartridge valves is set to revolutionize their functionality. Sensors and IoT connectivity will allow for real-time monitoring and predictive maintenance, enhancing operational efficiency.

2. Sustainable Manufacturing Practices

With an increasing focus on sustainability, manufacturers are seeking ways to reduce waste and energy consumption. Threaded cartridge valves, with their efficient flow control, play a vital role in promoting eco-friendly practices within the industry.

3. Advanced Materials

Research into new materials is paving the way for even more durable and resilient threaded cartridge valves. Innovations such as lightweight composites and corrosion-resistant alloys will further enhance their applicability in diverse environments.

Challenges in Implementing Threaded Cartridge Valves

Despite their numerous advantages, the implementation of threaded cartridge valves is not without challenges.

1. Initial Investment Costs

While these valves offer long-term savings, the initial investment can be a barrier for some manufacturers. It's essential to evaluate the return on investment to justify the expense.

2. Technical Expertise

Integrating threaded cartridge valves into existing systems may require specialized knowledge and skills. Manufacturers must ensure their teams are trained to handle installation and maintenance effectively.

Best Practices for Choosing and Installing Threaded Cartridge Valves

To maximize the benefits of threaded cartridge valves, manufacturers should consider the following best practices:

1. Assess System Requirements

Before selecting a threaded cartridge valve, it is crucial to assess the specific requirements of the system, including flow rates, pressure ratings, and compatibility with fluids.

2. Consult with Experts

Engaging with valve manufacturers or distributors can provide valuable insights into the best options available. Their expertise can guide manufacturers in making informed decisions.

3. Proper Installation

Ensuring proper installation is vital for optimal performance. Adhering to manufacturer guidelines and utilizing qualified personnel can prevent issues down the line.

FAQs about Threaded Cartridge Valves

1. What are threaded cartridge valves used for?

Threaded cartridge valves are primarily used to control fluid flow in hydraulic and pneumatic systems, chemical processing, and various manufacturing applications.

2. How do threaded cartridge valves differ from traditional valves?

Threaded cartridge valves have a modular design that allows for easier installation and maintenance compared to traditional valves, which often require extensive modifications.

3. Are threaded cartridge valves suitable for high-pressure applications?

Yes, many threaded cartridge valves are designed to withstand high pressures, making them suitable for demanding industrial environments.

4. Can threaded cartridge valves be used in corrosive environments?

Yes, threaded cartridge valves made from corrosion-resistant materials are specifically designed for use in harsh environments, including chemical processing.

5. What maintenance do threaded cartridge valves require?

Regular inspection for leaks, ensuring proper tightness, and checking for wear and tear are essential maintenance practices for threaded cartridge valves.

Conclusion

Threaded cartridge valves are undeniably changing the manufacturing landscape. Their ability to enhance efficiency, reduce costs, and provide flexibility makes them an invaluable component in various industrial applications. As technology advances and manufacturing processes evolve, the role of threaded cartridge valves will continue to expand, paving the way for a more efficient and sustainable future in manufacturing. By understanding their features, advantages, and applications, manufacturers can harness the full potential of threaded cartridge valves, driving innovation and efficiency in their operations.

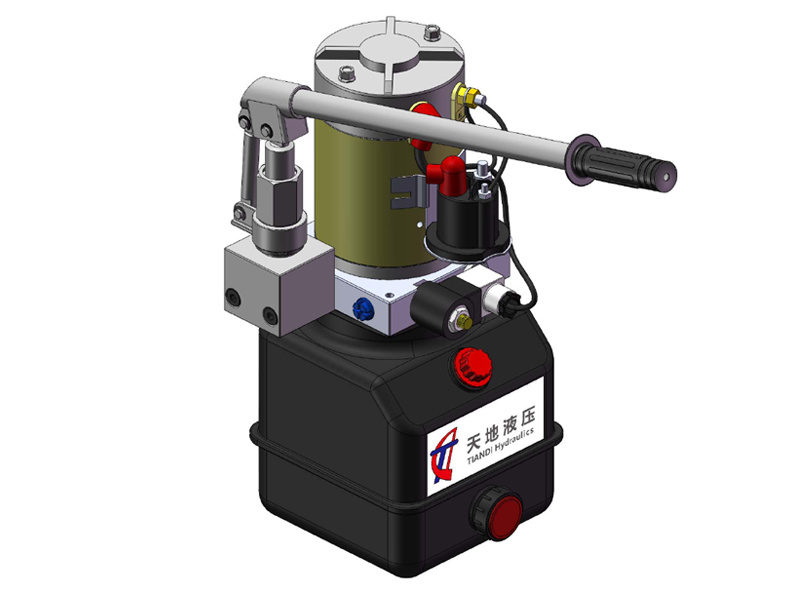

DC power unit & hand pump

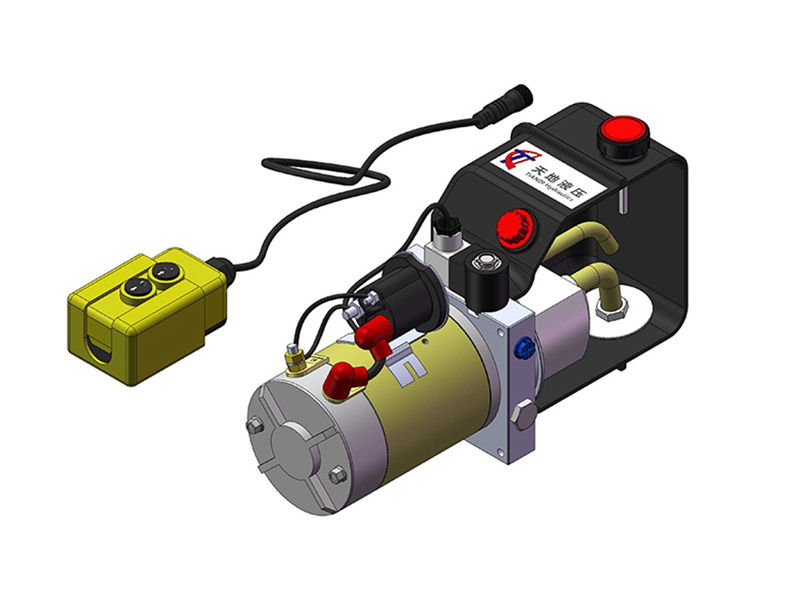

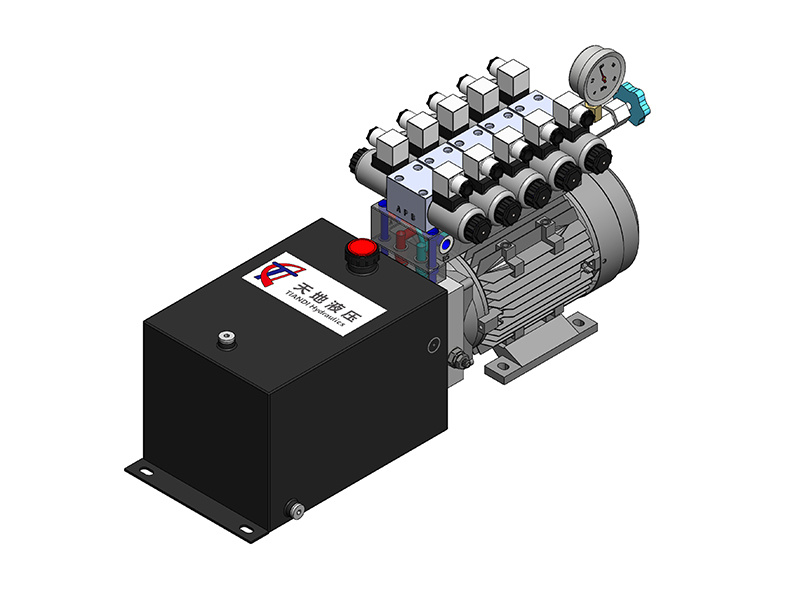

DC power unit & hand pump  DC power unit

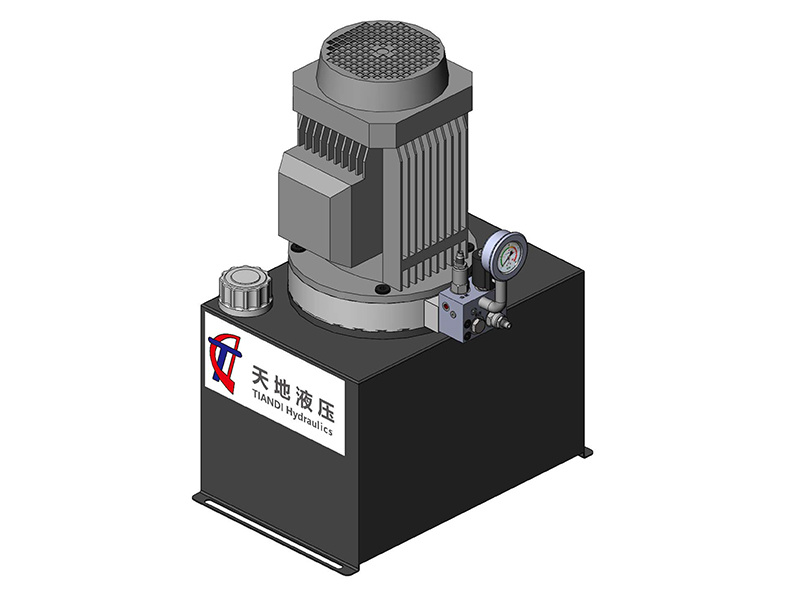

DC power unit  AC hydraulic station

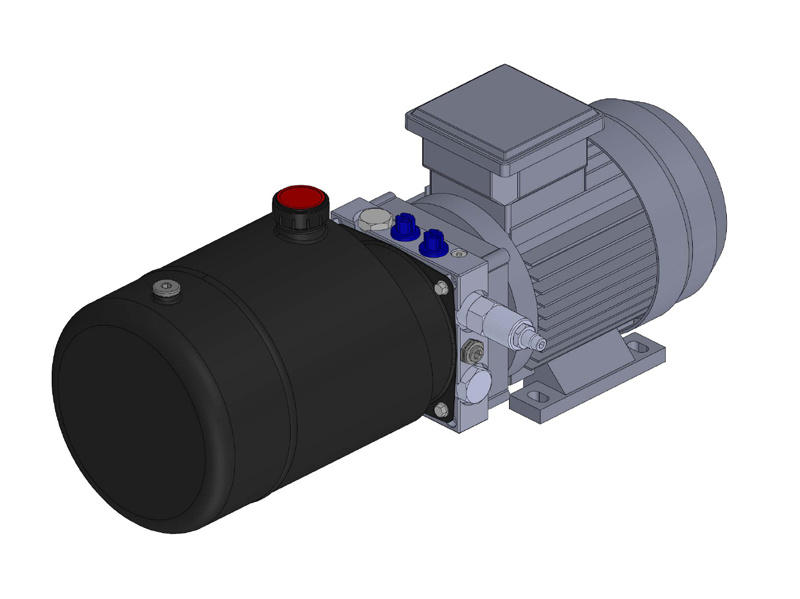

AC hydraulic station  Platform power unit

Platform power unit  AC power unit

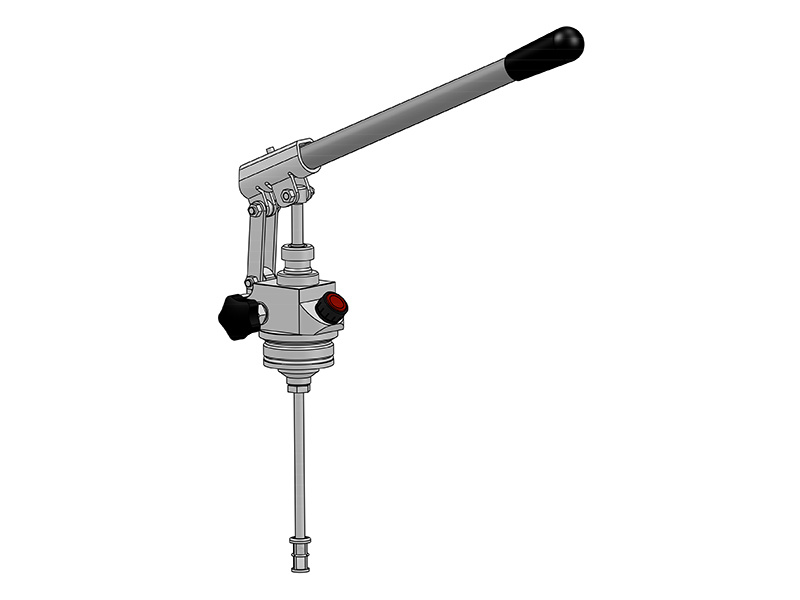

AC power unit  25CC/45CC double action hand p...

25CC/45CC double action hand p...  25CC/45CC single action hand p...

25CC/45CC single action hand p...  25CC double-plunger hand pump

25CC double-plunger hand pump  20CC single action hand pump

20CC single action hand pump  6CC single action hand pump

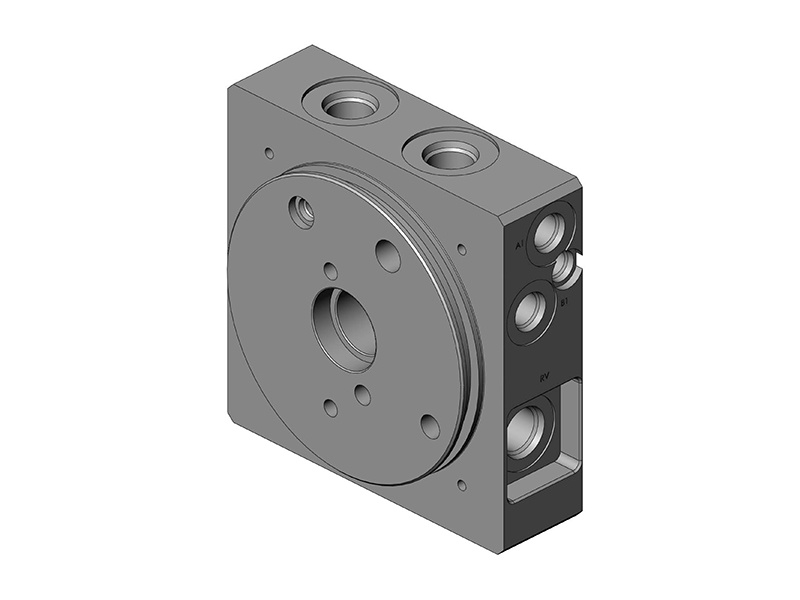

6CC single action hand pump  Hydraulic system circuit block

Hydraulic system circuit block  Power unit center block

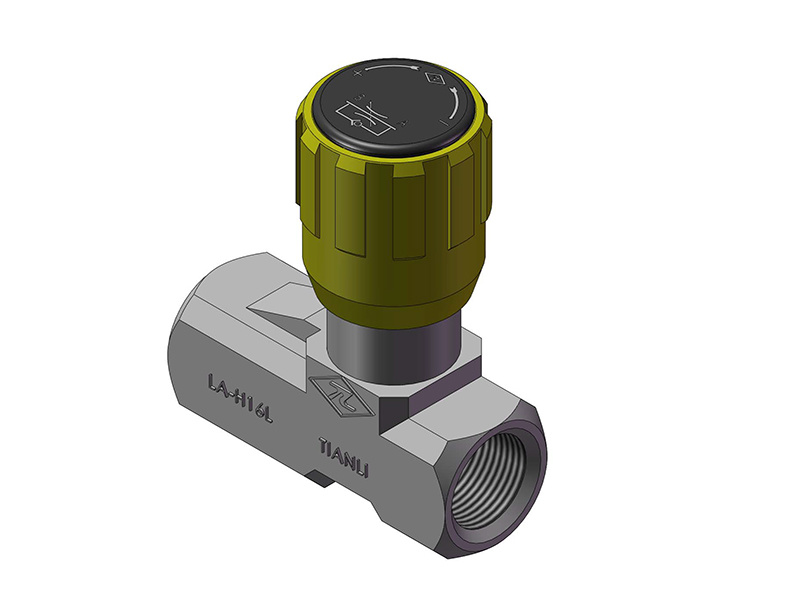

Power unit center block  Cartridge valve

Cartridge valve  Flow control valve

Flow control valve  Solenoid directional valve

Solenoid directional valve  DC motor

DC motor  Gear pump

Gear pump