Understanding Throttle Valves: Essential Insights for Industrial Applications

Date: 2026-01-10 Categories: Industry News Hits: 123

Throttle valves are integral components in various industrial systems, primarily utilized to regulate fluid flow and pressure within pipelines. These valves serve to manage the speed of fluid in a system, ensuring optimal performance and efficiency. Understanding the function and application of throttle valves can significantly enhance the operational reliability of industrial equipment.

One of the main purposes of throttle valves is to control the flow rate of liquids and gases, thereby affecting the pressure downstream. By adjusting the valve opening, operators can finely tune the flow to meet specific requirements. This capability is essential in processes where precise flow control is critical, such as in chemical manufacturing, oil and gas, and water treatment facilities.

When selecting a throttle valve for your application, several factors must be taken into account. First, consider the type of fluid being controlled. Different fluids have varying properties, including viscosity, density, and corrosiveness, which influence the selection of materials and designs for the throttle valve. Additionally, the operating pressure and temperature of the system are critical parameters that dictate the valve’s design specifications.

Another important consideration is the size of the throttle valve. The valve must be appropriately sized to match the flow requirements of the system. An undersized valve can lead to pressure drops and reduced efficiency, while an oversized valve can cause instability and erratic flow control. Accurate flow calculations and system assessments are essential during the selection process.

Installation and maintenance practices are also vital for the longevity and performance of throttle valves. Proper alignment, secure fittings, and regular inspections can help identify potential issues before they escalate, ensuring that the valve operates smoothly. It’s advisable to follow manufacturer guidelines and industry best practices for maintenance schedules.

Furthermore, advancements in technology have led to the development of smart throttle valves, which integrate sensors and control systems. These innovations allow for real-time monitoring and automated adjustments, improving the responsiveness and efficiency of fluid systems. Embracing these technologies can enhance operational capabilities, reducing downtime and increasing productivity.

In conclusion, throttle valves play a pivotal role in the control of fluid dynamics within industrial systems. Understanding their functionality, careful selection, and regular maintenance are crucial for optimizing performance. By staying informed about the latest advancements and best practices, professionals can ensure their systems operate efficiently and reliably.

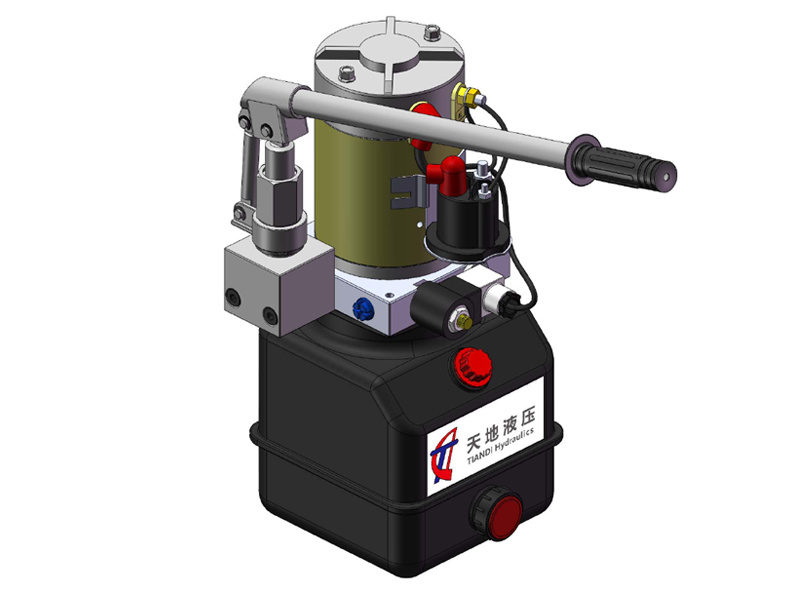

DC power unit & hand pump

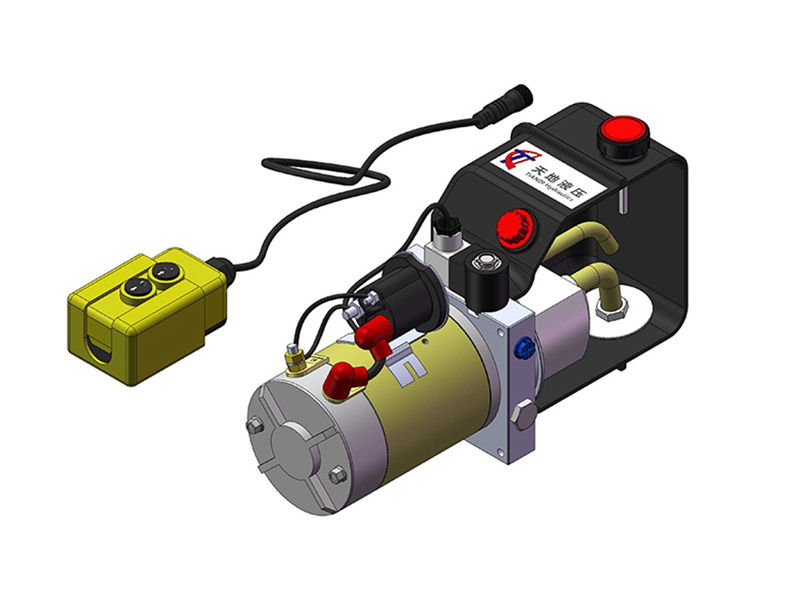

DC power unit & hand pump  DC power unit

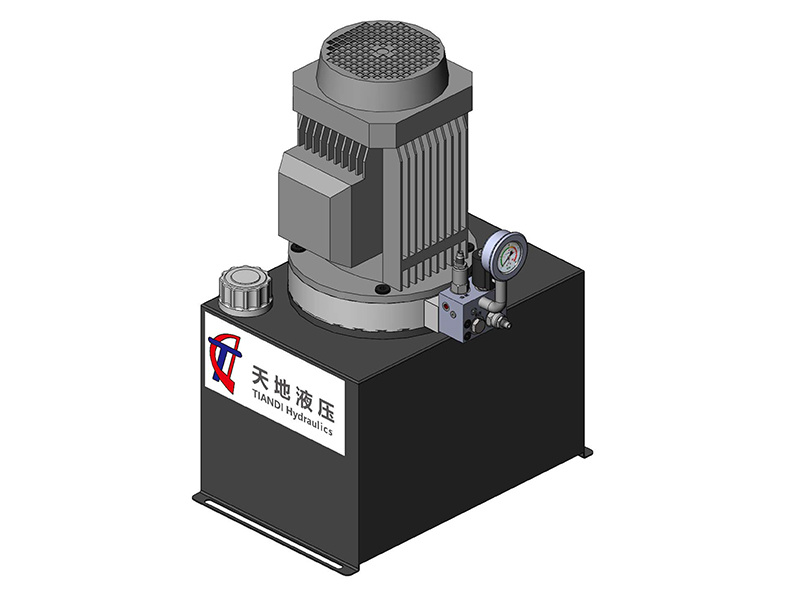

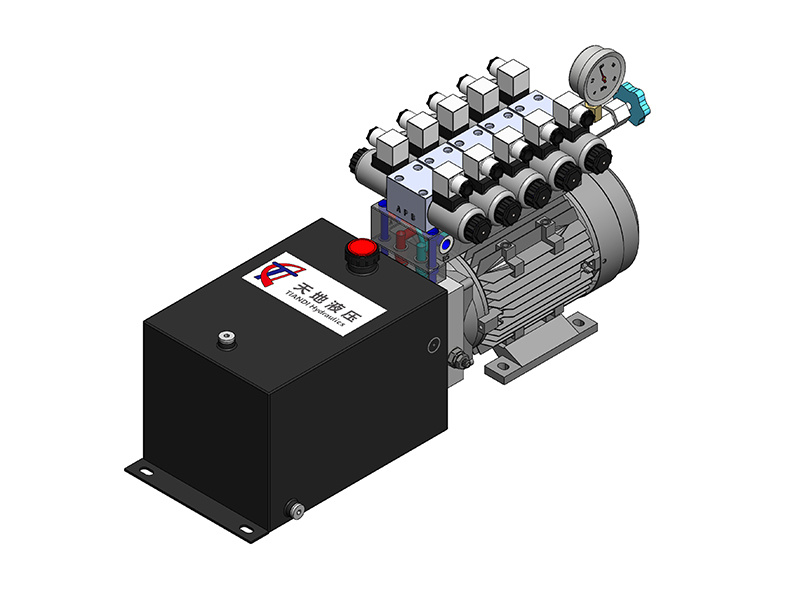

DC power unit  AC hydraulic station

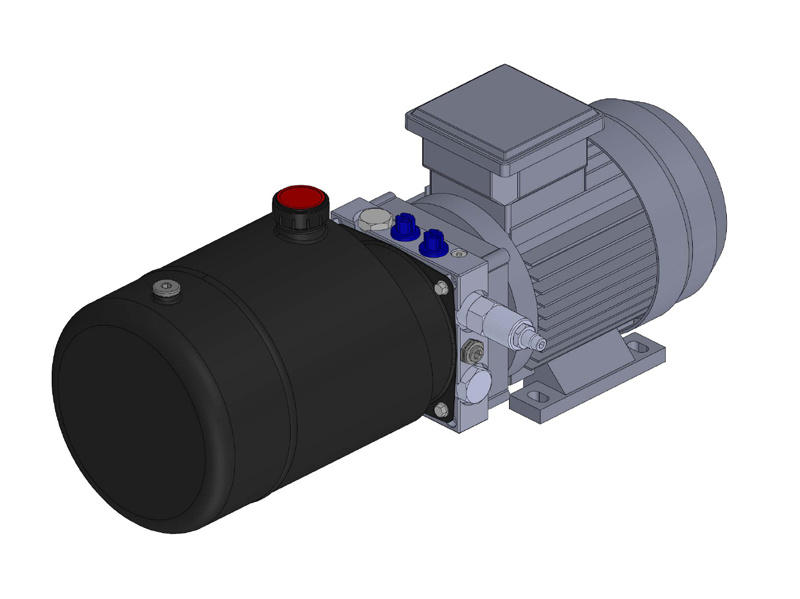

AC hydraulic station  Platform power unit

Platform power unit  AC power unit

AC power unit  25CC/45CC double action hand p...

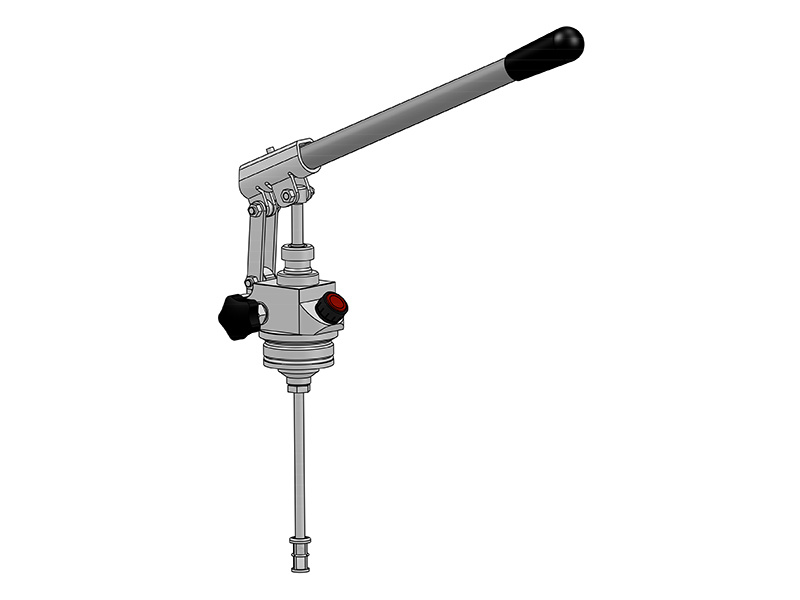

25CC/45CC double action hand p...  25CC/45CC single action hand p...

25CC/45CC single action hand p...  25CC double-plunger hand pump

25CC double-plunger hand pump  20CC single action hand pump

20CC single action hand pump  6CC single action hand pump

6CC single action hand pump  Hydraulic system circuit block

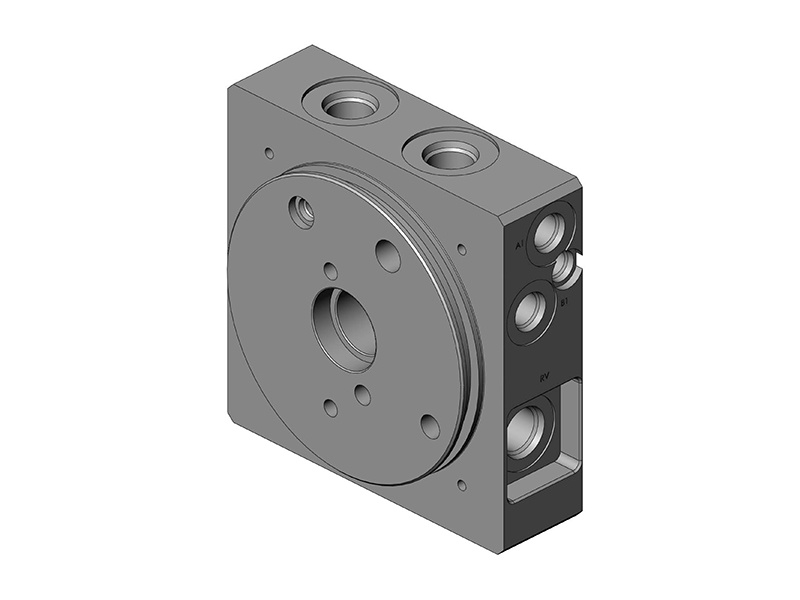

Hydraulic system circuit block  Power unit center block

Power unit center block  Cartridge valve

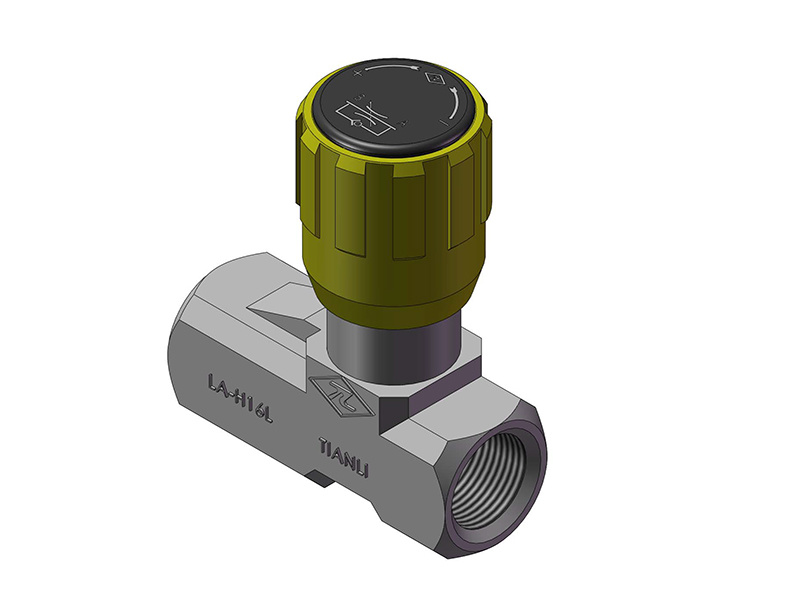

Cartridge valve  Flow control valve

Flow control valve  Solenoid directional valve

Solenoid directional valve  DC motor

DC motor  Gear pump

Gear pump